IonoFil – dielectric for wire EDM

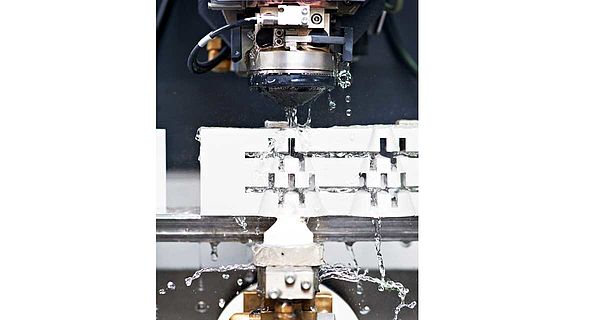

The dielectric for wire EDM!

Following on the experience and success with its dielectrics in the field of electrical discharge machining (EDM), oelheld has now set itself new targets. Whereas high-quality hydrocarbons have been successfully used for decades in cavity-sinking EDM, water is still used in wire EDM – and that despite the numerous associated disadvantages.

Particularly when machining carbide metal, cobalt leaching consequently causing corrosion present a problem that is difficult to overcome. That is why oelheld together with leading companies in the EDM field and the University of Louvain (Belgium) decided to solve this problem and set up a research project to develop a hydrocarbon-based dielectric that is designed specifically for the wire EDM technology.

The result is IonoFil, our dielectric for EDM wire cutting.

The service lives of carbide punches, in particular, can be enormously prolonged by preventing cobalt leaching. Laborious and cost-intensive deionisation of the water with resins, corrosion protection – before, during and after machining – and frequent changing of the medium are now things of the past thanks to this development. IonoFil as dielectric allows smaller spark gaps to be used, thus permitting far better precision machining, e.g. with closer radii. The quality of the surfaces increases to the same extent, with peak-to-valley roughnesses of down to Ra 0.1 μm being achieved far faster and easier than with water.

A convincing argument, particularly at a time when the industry is making ever higher quality demands on its suppliers and on the manufactured parts.

Downloads

Fore more informations download dielectrics brochure now (page 10)

Our dielectric IonoFil for EDM wire cutting is especially characterized by:

- no cobalt leaching with carbide metal

- better surface qualities

- no corrosion on workpieces and the machine

- better precision machining thanks to smaller spark gaps

- no microbiological attack

- reduced thermal shock

- less heat cracking